Vertical Air Compressors – What Should You Know Before Buying?

Claim your $100 Walmart Gift Card now and start shopping smarter! Limited time offer – act fast! Get a $100 Walmart Gift Card!

The Vertical air compressor is a type of air compressor that is designed with a vertical orientation, meaning that the compressor’s cylinder and tank are arranged vertically. This configuration allows the compressor to take up less floor space compared to horizontal models, making it suitable for environments where space is limited. Vertical air compressors are commonly used in various applications such as industrial manufacturing, automotive repair, construction, and home workshops to generate compressed air for powering pneumatic tools, inflating tires, and other tasks requiring compressed air.

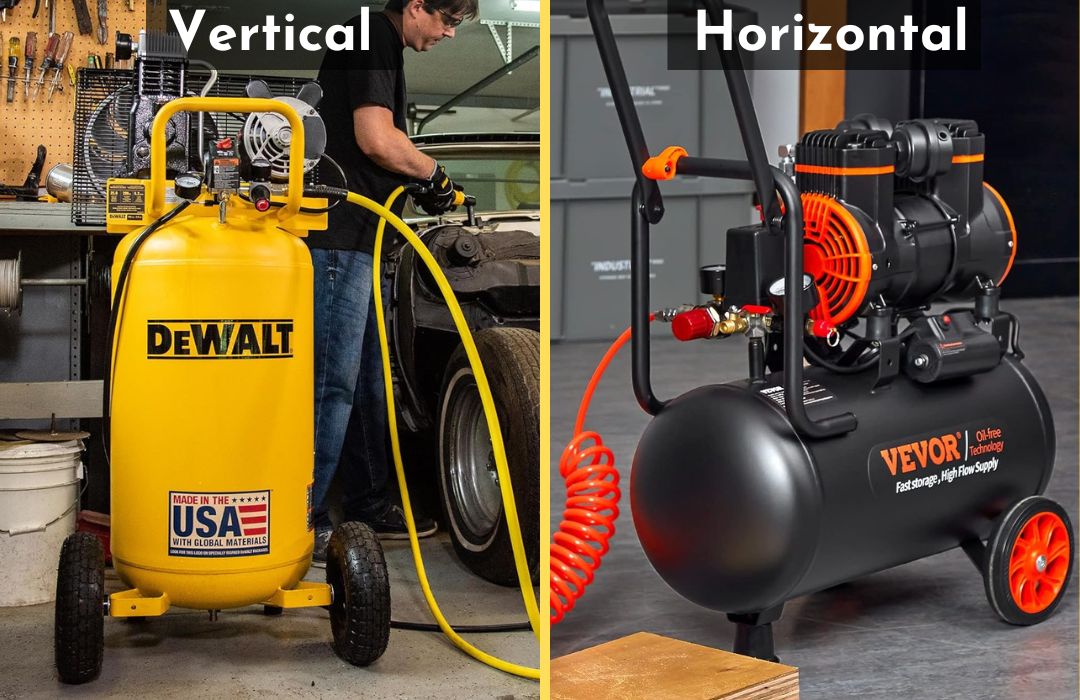

Which is better, a vertical or horizontal air compressor?

Whether a vertical or horizontal air compressor is better depends on the intended use, available space, mobility requirements, and personal preferences. Here’s a comparison to help you decide:

Vertical Air Compressor:

1. Space-saving design: Vertical compressors typically take up less floor space compared to horizontal models, making them suitable for environments with limited space.

2. Stability: Vertical compressors often have a lower center of gravity, providing greater stability, especially on uneven surfaces.

3. Mobility: Vertical compressors are generally easier to move around since they have a smaller footprint and can be equipped with wheels for enhanced portability.

4. Ease of maintenance: Vertical compressors may offer easier access to components for maintenance and repairs due to their vertical orientation.

Horizontal Air Compressor:

1. Stability: Horizontal compressors may offer better stability when operating at high pressures or with heavy loads due to their wider base.

2. Accessibility: Some users find it easier to access controls and connections on a horizontal compressor, especially if they are mounted at waist height.

3. Versatility: Horizontal compressors may be more versatile in terms of placement options since they can be positioned under workbenches or against walls.

4. Tank size: Horizontal compressors often have larger tank capacities compared to vertical models, which can be advantageous for applications requiring longer periods of continuous operation without refilling.

What Size vertical air compressor should you choose?

20 Gallon Vertical Air Compressor:

Ideal for: Light to medium-duty tasks such as home workshops, DIY projects, and small-scale pneumatic tool usage.

Suitable for: Inflating tires, operating brad nailers, staplers, and other small air tools, as well as powering paint sprayers.

Benefits: Compact Size makes it perfect for environments with limited space, such as garages or workshops. Provides enough capacity for occasional use without taking up excessive space.

30 Gallon Vertical Air Compressor:

Ideal for: Medium-duty tasks in automotive repair shops, small manufacturing operations, and construction sites.

Suitable for: Running impact wrenches, air ratchets, sanders, and other moderate air tools. Suitable for tasks requiring longer periods of continuous operation.

Benefits: Offers a balance between capacity and portability, making it versatile for a range of applications. Provides sufficient air supply for extended use without frequent refills.

10 Gallon Vertical Air Compressor:

Ideal for: Light-duty tasks and portable applications such as home renovations, trim work, and inflation tasks.

Suitable for: Operating brad nailers, airbrushes, tire inflation, and other light-duty pneumatic tools.

Benefits: Extremely portable and suitable for small-scale projects where mobility is essential. Ideal for homeowners and hobbyists who need occasional compressed air.

60 Gallon Vertical Air Compressor Tank:

Ideal for: Heavy-duty applications in industrial settings, automotive repair shops, and large-scale construction projects.

Suitable for: Running air impact wrenches, sandblasters, paint sprayers, and other high-demand air tools. Ideal for continuous operation in demanding environments.

Benefits: Provides ample air supply for heavy-duty tasks, minimizing downtime for refilling. Suitable for powering multiple air tools simultaneously or for high-volume tasks.

80 Gallon Vertical Air Compressor Tank:

Ideal for: Industrial manufacturing, commercial workshops, and large-scale construction projects requiring high-volume compressed air.

Suitable for: Operating large air tools such as pneumatic drills, grinders, sanders, and spray guns. Ideal for continuous operation in demanding environments.

Benefits: Offers maximum air capacity and efficiency, minimizing downtime and ensuring uninterrupted operation for heavy-duty applications.

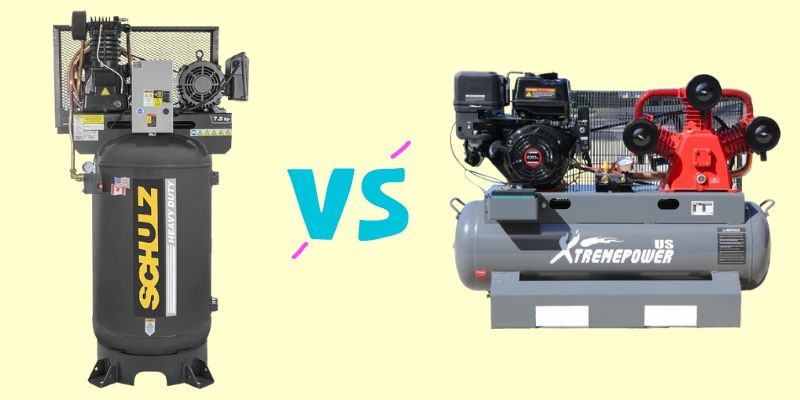

Vertical Gas Powered Air Compressor:

Ideal for: Remote job sites, outdoor applications, and environments where electrical power may not be readily available.

Suitable for: Various pneumatic tasks, including construction, agriculture, and emergency roadside assistance.

Benefits: Provides portability and versatility for applications where electricity is not accessible. Suitable for outdoor use and ideal for contractors or professionals working in remote locations.

Can I Lay A Vertical Air Compressor On Its Side?

Laying a vertical air compressor on its side is generally not recommended, as it can potentially damage the compressor and affect its performance. Here are a few reasons why:

1. Oil Lubrication: Many vertical air compressors use oil lubrication systems to ensure smooth operation and reduce wear on internal components. When you lay the compressor on its side, there’s a risk of oil leakage or uneven distribution within the compressor, which can lead to inadequate lubrication or damage to the motor and other moving parts.

2. Air Filter and Intake: Placing the compressor on its side can disrupt the airflow and intake mechanisms, potentially causing air filter clogging or reducing the efficiency of air intake. This can result in decreased performance and increased strain on the compressor motor.

3. Drainage: Air compressors accumulate moisture and condensation over time, which needs to be drained periodically. That prevents corrosion and damage to the tank. When you lay a vertical compressor on its side, it may become difficult to access the drainage valve, leading to inadequate maintenance and potential problems with moisture buildup.

4. Safety Concerns: Laying a vertical air compressor on its side can create stability issues, especially if it’s not properly secured or supported. This poses a safety risk, as the compressor may tip over during operation, potentially causing injury or damage to surrounding equipment.

Note: If you need to transport a vertical air compressor, laying it down temporarily during transit is generally okay. However, it’s crucial to secure the compressor properly to prevent it from shifting or tipping over. Ensure that it’s adequately padded and supported to prevent damage to internal components.

FAQs about Vertical Air Compressors

The primary advantage of a vertical air compressor is its space-saving design. Vertical compressors typically take up less floor space compared to horizontal models, making them ideal for environments with limited space.

For a home workshop, a 20 or 30-gallon vertical air compressor would be suitable for light to medium-duty tasks such as operating brad nailers, inflating tires, and powering small air tools.

Yes, vertical air compressors with larger tank capacities, such as 60 or 80-gallon models, are suitable for heavy-duty industrial applications. They can power large air tools and operate continuously in demanding environments.

Yes, many vertical air compressors are designed with portability in mind. Smaller capacity models, such as 10 or 20-gallon compressors, are often equipped with handles and wheels for easy transport.

Can I lay down a vertical air compressor horizontally?

It’s generally not recommended to lay down a vertical air compressor horizontally, especially during operation. Doing so can cause issues with oil distribution, air intake, and drainage, which may affect performance and potentially damage the compressor.

Maintenance requirements for vertical air compressors typically include: Regular inspection of components.Checking and replacing air filters. Draining condensation from the tank. Lubricating moving parts as needed.

Gas-powered air compressors are typically designed for outdoor use or well-ventilated areas due to emissions from the engine.

Hi, Eddie T. Jones and I am the author of homegearsolution.com. I have been working with household appliances, tools, outdoor gear, and gardening tools for several years. I publish unbiased comparisons based on user reviews, expert reviews, and test results. I hope you like the website.

Best regards, Eddie T. Jones